Industrial Hard Chrome Plating

ChromeTech of Wisconsin is your hard chrome plating expert. Request a quote today.

ChromeTech of Wisconsin is your hard chrome plating expert. Request a quote today.

Proprietary Hard Chrome Plating Chemistry

We set ourselves apart with our proprietary chemistry that guarantees an Rc hardness of 70-72, with a semi-bright finish.

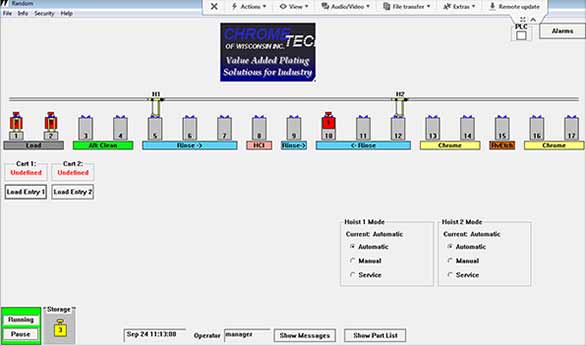

We use both manual and automated hard chrome plating equipment for our hard chrome plating projects. This allows us to plate single pieces, such as a one-piece salvage job, or plate a high volume of parts at once.

Your largest pieces are no problem with our manual line. We can process parts with diameters up to 55”, lengths up to 132” and weights up to 8000 pounds.

Increased hardness, increased wear resistance, reduced friction, protection from corrosion, and dimensional build-up make hard chrome plating an excellent choice for a wide variety of applications. Hard chrome can be applied in thicknesses ranging from .00005” to .070” on most metals including:

- Stainless steel

- Copper

- Brass

- Cast iron

- Cast Steel

- Inconel

- Nickel

- Many other exotic materials

What is hard chrome plating? Hard chrome plating is a form of electroplating, a process in which an electric current is applied to an object submerged in a metal ion solution. The electricity facilitates the conversion of the metal ions into solid metal atoms on the surface of the object. In hard chrome plating specifically, these metal ions are chromium.